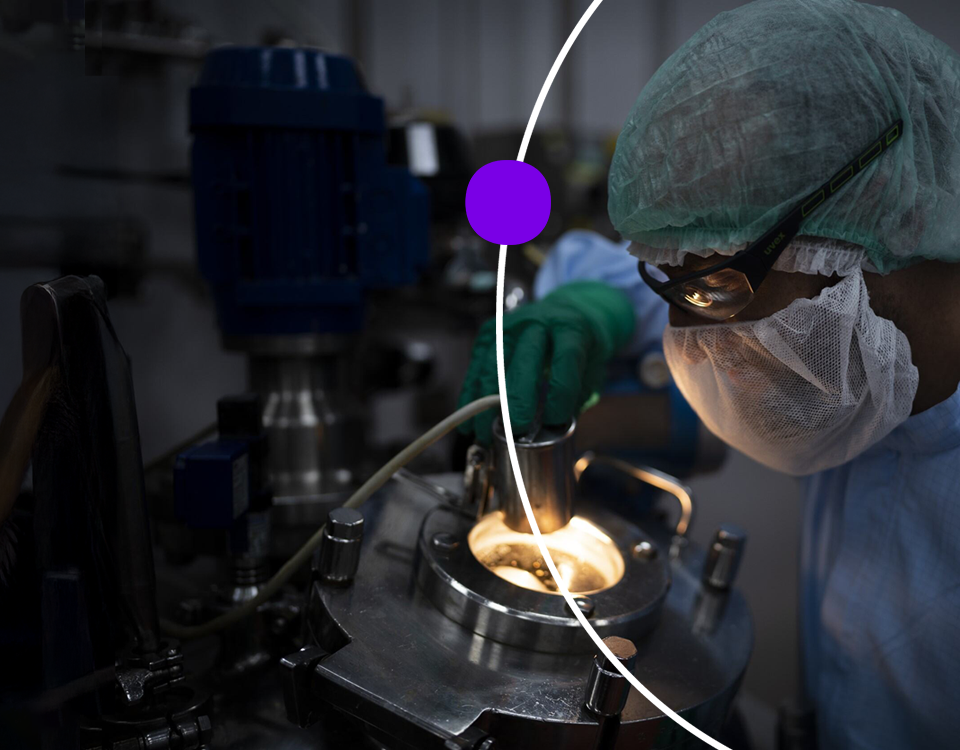

Manufacturing and Supply

Wo Wunder der Wissenschaft

für Patient*innen Realität werden

Chemical Technician Trainee (Career Conversion Program)

Auf einen Blick:

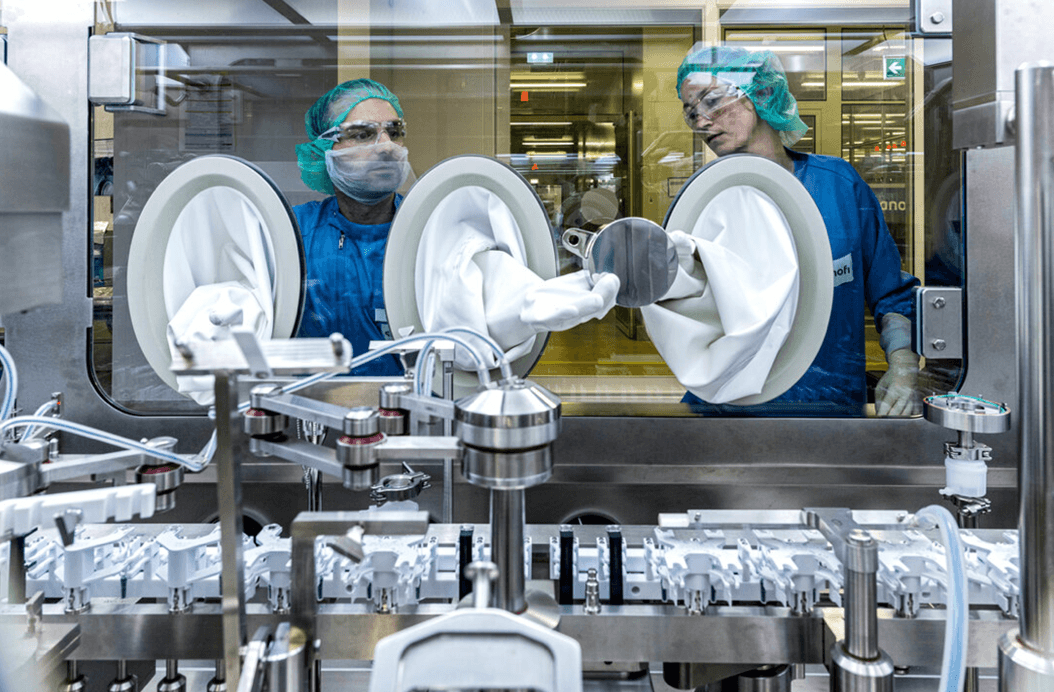

Unsere Teams produzieren und liefern jedes Jahr über 4 Milliarden Einheiten an Medikamenten und Impfstoffen und sorgen dafür, dass jede Innovation die Menschen erreicht, die sie am dringendsten benötigen. Unsere hochmodernen Produktionsstätten, KI-gestützten Smart Factories und wegweisenden Automatisierungstechnologien setzen neue Maßstäbe – damit Behandlungen Patient*innen schneller, sicherer und nachhaltiger als je zuvor erreichen. Hier kannst Du mit Deinen Fähigkeiten, Deinen Ambitionen und Deiner Leidenschaft die Zukunft des Gesundheitswesens mitgestalten.

Job title: Chemical Technician Trainee (Career Conversion Program)

Location: Singapore

About the Job

We deliver 4.3 billion healthcare solutions to people every year, thanks to the flawless planning and meticulous eye for detail of our Manufacturing & Supply teams. With your talent and ambition, we can do even more to protect people from infectious diseases and bring hope to patients and their families.

Main Responsibilities

As a member of the production shift team, the job holder will operate and monitor the chemical production activities in the plant, ensuring that the product is manufactured within set production schedule and to the required standards of quality in a safe, efficient, responsible and cost effective manner.

The job holder will report to the Shift Supervisor and his deputy working alongside with other chemical technicians.

1. Operate the different streams of the plant for their specific processes. At minimum, he should be able to run:

3 ENOX stages and 1 SCG stage independently (for SCP)

All ENOX stages independently (for Enox Plant)

Each of these processes comprises the following activities.

Handover checks computerized and/or manual.

Obtaining, following and completing process related documentation.

Pre and post batch cleaning of vessels and lines.

Pre batch checks.

Charging vessels either manually or via a pump.

Post charging checks and taking corrective action where necessary.

Adjusting and monitoring process conditions as required to start the process.

Monitoring process; both with computer and manually observing temperature, pressure, flow, pH, volume, colour, moisture content and adjusting the parameters accordingly.

Carrying out routine sampling and Bulk packing and testing of samples as required.

Recognise end point of the reaction and altering process parameter to stop reaction.Transferring product to the next stage.

2. Comply with HSE and quality policies and defined procedures. Bring out unsafe conditions and acts / procedures for correction.

3. Record all operational and analytical data on the appropriate documents and inform the Shift Supervisor of any process abnormalities.

4. Maintain product separation and accurate labelling of all documents, bags and vessels at all times.

5. Carry out routine checks and scheduled cleaning procedures including cleanrooms.

6. Request and collect raw materials and consumables, observe clean areas procedures, monitor raw materials stock and notify Shift Supervisor for any abnormalities.

7. Notify Shift Supervisor of requirements for maintenance. Prepare equipment before maintenance work e.g. depressurizing, cleaning of lines and equipment, de-energizing, LOTO etc.

8. Perform basic maintenance of equipment using tools such as TPM.

9. At the Shift Supervisor's request, to carry out on-the-job training of other Chemical Technicians, incorporating cGMP and safety procedures.

10. To observe cGMP and Health & Safety rules and regulations at work at all times in accordance with Company set standards.

11. To be aware of the potentially hazardous nature of the chemicals in the area and must take the appropriate precautions when using them.

12. Maintain housekeeping of the plant and provide suggestions for improvements.

13. To operate ancillary facilities e.g. water system, tank farms, solvent recovery etc.

14. Able to perform manual handling tasks including lifting of materials which are weights up to 25kg and be medically fit to be part of Company’s firefighter CERT team.

About You

Minimum NITEC or Higher NITEC in Chemical Processing or related and 2 years of prior relevant experience preferably in the Chemical or related industries. Should have good understanding of safe working practices and cGMP required of a fine chemical plant.

Must be prepared to work shifts.

Must be resourceful, conscientious, dedicated and a good team player.

Adequate formal and on-the-job training on the chemical processes will be given.

Use of process control systems for operation of plant equipment

Operation of manufacturing equipment such reactors, centrifuges, filters, dryers etc

Cleaning and maintaining cleanliness and condition of cleanroom facility

Implement cleaning and changeover of equipment

Apply GMP in manufacturing processes

Manage materials and materials flow according to established SOP and BRS

Able to identify and manage hazards that may occur within biopharmaceutical plant

Verify that routine manufacturing processes are consistently within a state of control

In-process analysis to verify that results are within targets

Able to perform line tracing using P&ID

Able to do simple mechanical task such as filter changes.

Communicate information with others to respond to general inquiries and obtain specific information

Digital literacy: Able to use computer software to perform basic functions

Interpersonal skills to be able to work with the team and with other departments

Basic problem solving to solve simple problems

Mehr Informationen über diesen Standort

Warum bei uns arbeiten?

- Wir stellen nicht nur Medikamente her – wir bewirken etwas. Unser globales Netzwerk modernster Produktionsstätten sorgt dafür, dass Patient*innen die Behandlungen erhalten, die sie brauchen – genau zur richtigen Zeit.

- Innovation treibt uns an. Von KI-gestützter Fertigung bis hin zu weltweit führenden Produktionsmethoden setzen wir neue Maßstäbe in Effizienz und Leistung.

- Hier wachsen Karrieren. Ob in der Produktion, Qualitätssicherung, Ingenieurtechnik oder in der Supply Chain– arbeitest Du mit erstklassigen Talenten zusammen, entwickelst Deine Fähigkeiten weiter und gestaltest die Zukunft der Pharmaindustrie mit.

- Wir tun, was richtig ist. Sicherheit, Nachhaltigkeit, Vielfalt, Gleichberechtigung und Inklusion stehen im Mittelpunkt unseres Handelns – für ein Arbeitsumfeld, in dem alle erfolgreich sein können.

All-In für Vielfalt

Bei Sanofi führen unterschiedliche Perspektiven zu den besten Lösungen für Patient*innen. Erfahre von Monique Vessey, unserer Leiterin der Supply Chain -Transformation, wie ihre persönliche Geschichte ihre Arbeit bei der Bereitstellung lebenswichtiger Medikamente prägt.

"Manufacturing & Supply bildet die Brücke zwischen der Wissenschaft in unseren Forschungslaboren und den Menschen und Gemeinschaften, die wir versorgen."

Brendan O’Callaghan

Executive Vice President of Manufacturing and Supply

Mehr erfahren

Karriere in Manufacturing and Supply

Entdecke wie Sanofi die pharmazeutische Produktion und Supply Chain mit modernster Technologie, digitaler Innovation und nachhaltigen Prozessen transformiert. Ergreife Deine Chance, lebensverändernde Medikamente effizient und verantwortungsvoll bereitzustellen.

Biopharma-Innovation mit McLaren Racing beschleunigen

Was haben die Formel 1 und die biopharmazeutische Industrie gemeinsam? Geschwindigkeit, Präzision und das Streben nach Exzellenz. Erfahre wie Sanofi gemeinsam mit McLaren Racing die Medikamentenentwicklung mit modernster cutting-edge-Wissenschaft revolutioniert.

Mach mit bei unserer Talent Community

Was können wir gemeinsam erreichen? Unsere Teams arbeiten an Projekten, die Menschenleben nachhaltig verändern. Registriere Dich jetzt und erhalte die neuesten Stellenangebote, sobald diese veröffentlicht werden.