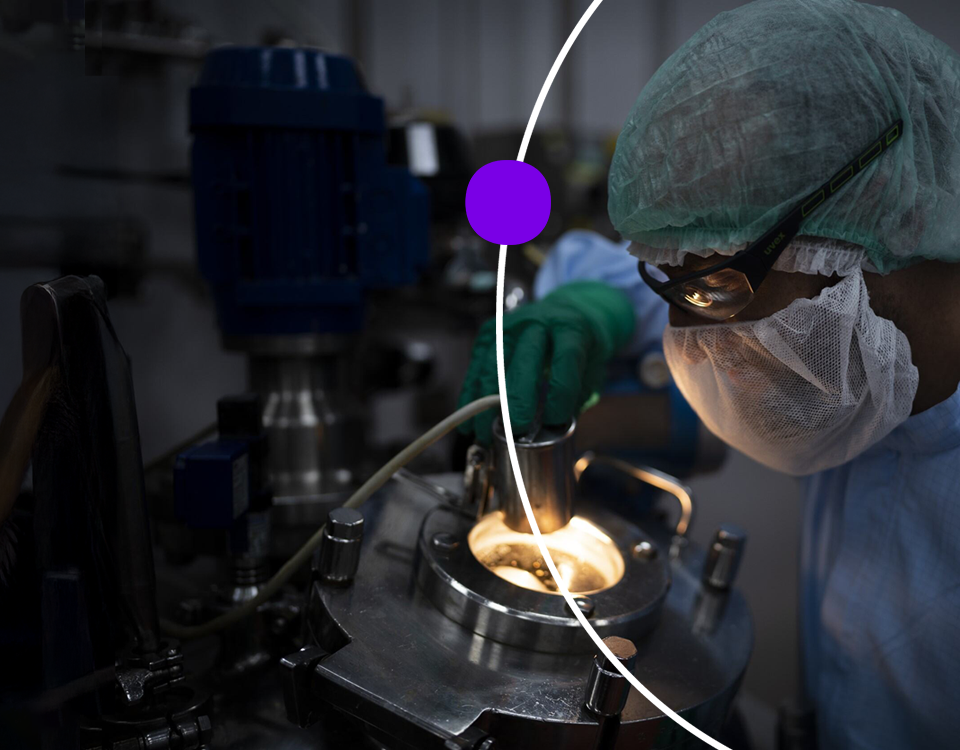

Activités Industrielles

Là où les miracles

de la science

deviennent une réalité pour les patients

Methods and Reliability Engineer

En bref

Nos équipes produisent et livrent chaque année plus de 4 milliards de médicaments et de vaccins, veillant à ce que chaque avancée soit accessible à ceux qui en ont le plus besoin. Grâce à des infrastructures ultra-modernes, des usines intelligentes pilotées par l’IA et une automatisation de pointe, nous repoussons les limites pour garantir que nos traitements parviennent aux patients plus rapidement, en toute sécurité et de manière plus durable que jamais. C’est ici que votre expertise, votre ambition et votre passion peuvent façonner l’avenir de la santé.

Job Title: Reliability and Methods Engineer

Location: Swiftwater, PA

About the Job

We deliver 4.3 billion healthcare solutions to people every year, thanks to the flawless planning and meticulous eye for detail of our Manufacturing & Supply teams. With your talent and ambition, we can do even more to protect people from infectious diseases and bring hope to patients and their families.

The Reliability & Methods Engineer is responsible of optimizing and implementing Preventive and Predictive Maintenance of process equipment in order to achieve the right maintenance strategy to support the business without compromising safety or compliance. The role is expected to be able to identify issues or needs and initiates projects or programs to address them. The candidate shall be able to evaluate minor capital project requests and lead the implementation of the project withing site compliance requirements. The individual works collaboratively to complete assignments and oversees the successful completion of tasks. Using solid analytical skills, the incumbent must be able to recognize problems of moderate scope and complexity, and independently, develop potential solutions and courses of action. This individual represents the work group on multi-disciplinary and cross-functional teams and uses established relationships to influence and lead teams and stakeholders with fact-based, business value knowledge

The Reliability & Method Manager will be responsible of the Formulation Filling Inspection and Packaging (FFIP) operations process equipment & Facilities. The incumbent will oversee, track and troubleshoot daily equipment failures and propose corrective actions in coordination with maintenance team. This position will develop and maintain a strategic equipment Lifecycle master plan to ensure process equipment, parts and technology replacement are proactively planned and implemented.

The candidate must possess knowledge of equipment lifecycle analysis, predictive and preventative maintenance strategies for equipment including Formulation Tanks, Autoclaves, Filling lines, Inspection machines, Packaging lines, Utilities and Facilities.

We are an innovative global healthcare company with one purpose: to chase the miracles of science to improve people’s lives. We’re also a company where you can flourish and grow your career, with countless opportunities to explore, make connections with people, and stretch the limits of what you thought was possible. Ready to get started?

Main Responsibilities:

Overall plant reliability (equipment, utilities, and facilities)

Through individual contribution and leading teams, utilize RCM tools, the CMMS, other historical data, predictive technologies, and industry best practices to determine and implement optimum equipment performance, maintenance strategies, and work processes. This includes equipment definition/hierarchy, criticality of equipment, maintenance strategydevelopment, and spare parts.

Monitoring of M&R value, performance, and cost effectiveness

Liaison with the Engineering department where it will be required to review all new projects for long term maintenance needs. This will include such things as equipment, parts usage, (both manufacturer/model and application), maintenance access, training assessment needs, installation correlation to design (or the subsequent documentation with as built drawings and commissioning), spare parts recommendation, preventative maintenance requirements (along with the need for any special tooling and labor requirements).

Maintenance strategy and continuous optimization

Key stakeholder for the life-cycle management of industrial assets. This includes being the Maintenance liaison for equipment/system modifications and Preventative Maintenance (PM) review/modification, to improve operation, uptime, efficiency, etc., or to decrease parts usage, specific breakdown type, labor hours and equipment cost of operation

Identification and prioritization of RE and CI initiatives

Reliability technology (PdM, data analytics, digital WO)

Active participation in the implementation of PdM innovation technologies with cross functional groups. Perform statistical analysis with data mining tools such as OSI PI or SEEQ.

Root cause analysis and corrective actions for breakdowns

Spare parts inventory optimization (criticality, stocking, FE)

Related KPIs & Metrics

Equipment & facility reliability (including financial impacts)

Standard reliability engineering metrics (MTBF, bad actors, OOT)

Rate of deviations and discards with reliability root causes

Reduction in reactive/emergency corrective work orders

Spare parts inventory metrics

About You

Education & Experience & Certification

Technical Expertise: knowledge of engineering & maintenance principles in a manufacturing environment. Pharmaceutical manufacturing knowledge preferred but not required. Knowledge of industrial maintenance methodologies.

Regulatory Knowledge: Familiarity with pharmaceutical industry regulations, including GMP and FDA standards preferred but not required.

Problem-Solving: Excellent analytical and problem-solving skills to address technical issues.

Experience with RE tools (FMEA, RCA, PM optimization)

Minimum B.S., Engineering Degree and/or Equivalent Science/Technical Degree with experience relevant to life sciences and/or vaccines manufacturing, or with appropriate supplemental industrial experience. In lieu of technical degree, 10+ years of experience in manufacturing maintenance.

Minimum 3 years’ experience in Manufacturing.

Why Choose Us?

Bring the miracles of science to life alongside a supportive, future-focused team.

Discover endless opportunities to grow your talent and drive your career, whether it’s through a promotion or lateral move, at home or internationally.

Enjoy a thoughtful, well-crafted rewards package that recognizes your contribution and amplifies your impact.

Take good care of yourself and your family, with a wide range of health and wellbeing benefits including high-quality healthcare, prevention and wellness programs and at least 14 weeks’ gender-neutral parental leave.

Sanofi Inc. and its U.S. affiliates are Equal Opportunity and Affirmative Action employers committed to a culturally diverse workforce. All qualified applicants will receive consideration for employment without regard to race; color; creed; religion; national origin; age; ancestry; nationality; marital, domestic partnership or civil union status; sex, gender, gender identity or expression; affectional or sexual orientation; disability; veteran or military status or liability for military status; domestic violence victim status; atypical cellular or blood trait; genetic information (including the refusal to submit to genetic testing) or any other characteristic protected by law.

#GD-SP

#LI-SP

#LI-Onsite

#vhd

All compensation will be determined commensurate with demonstrated experience. Employees may be eligible to participate in Company employee benefit programs, and additional benefits information can be found here.

En savoir plus

sur ce site

Pourquoi nous rejoindre ?

- Nous ne faisons pas que fabriquer des médicaments—nous créons un impact. Grâce à notre réseau international d’installations de pointe, nous veillons à ce que les patients reçoivent les traitements dont ils ont besoin, au moment où ils en ont besoin.

- L’innovation est notre moteur. De la fabrication pilotée par l’IA aux méthodes de production inédites, nous repoussons les limites de l’efficacité et de la performance.

- Ici, vous évoluez. Que ce soit en production, en qualité, en ingénierie ou en supply chain, vous collaborerez avec des experts de renom, développerez vos compétences et contribuerez à façonner l’avenir de l’industrie pharmaceutique.

- Nous faisons ce qui est juste. Sécurité, durabilité, diversité, équité et inclusion sont au cœur de notre engagement, garantissant un environnement où chacun peut s’épanouir.

Tous engagés pour la diversité

Chez Sanofi, la diversité des perspectives est une source d’innovation au service des patients. Découvrez Hamza Laajaj, Chef de projet déploiement applicatif à Neuville-sur-Saône, et son engagement pour un environnement inclusif où chaque voix compte. Pour lui, c’est en embrassant la diversité que nous libérons l’innovation et repoussons les limites de la santé.

"Nous faisons ce qui est juste. Sécurité, développement durable, diversité, équité et inclusion sont au cœur de notre engagement, garantissant un environnement où chacun peut s’épanouir."

Brendan O’Callaghan

Executive Vice President of Manufacturing and Supply

En savoir plus

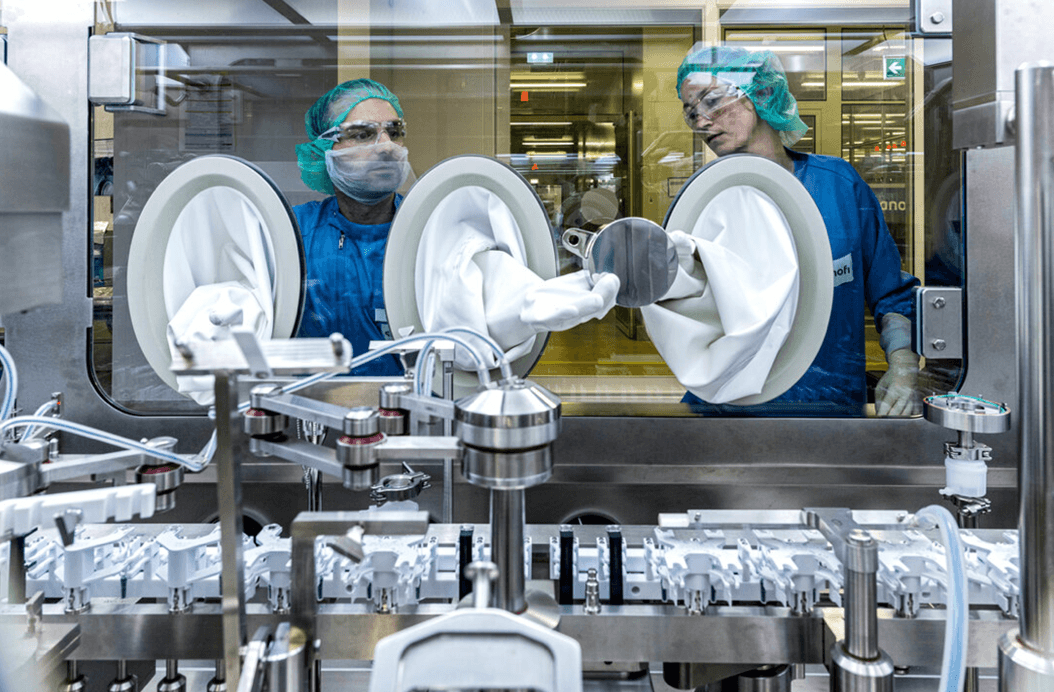

Carrières dans les Activités Industrielles

Découvrez comment Sanofi révolutionne la production pharmaceutique et les chaînes d’approvisionnement grâce aux technologies de pointe, à l’innovation digitale et à des pratiques durables. Rejoignez-nous pour contribuer à la distribution efficace et responsable de médicaments essentiels.

Accélérer l’innovation biopharma avec McLaren Racing

Qu’ont en commun la Formule 1 et la biopharma ? La vitesse, la précision et l’excellence. Découvrez comment Sanofi et McLaren Racing repoussent les limites du développement de médicaments grâce aux sciences de la performance de pointe.

Rejoignez notre communauté

de talents

Que pourrions-nous accomplir ensemble ? Chaque Sanofien travaille sur des projets qui ont un véritable impact sur la vie des gens.

Inscrivez-vous dès aujourd'hui et découvrez nos dernières opportunités dès qu'elles seront disponibles.